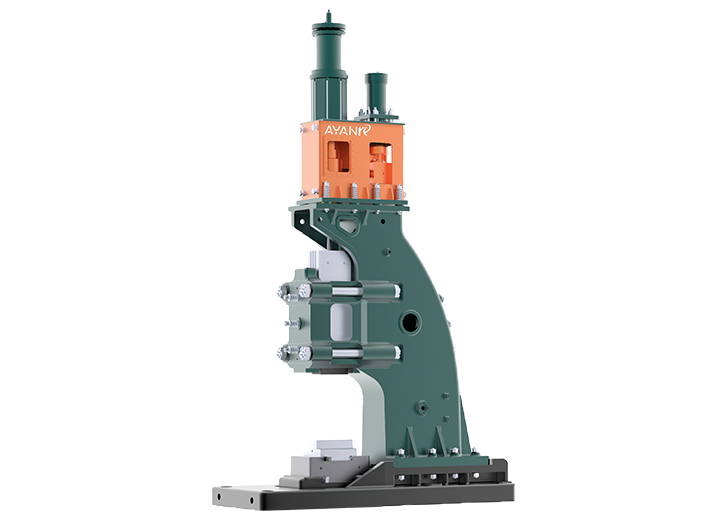

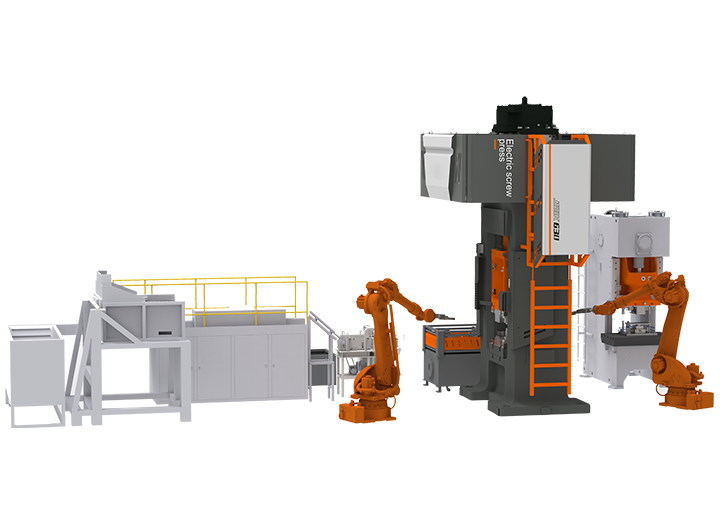

CNC Electric Serew Press (J58KA 250-4000T)

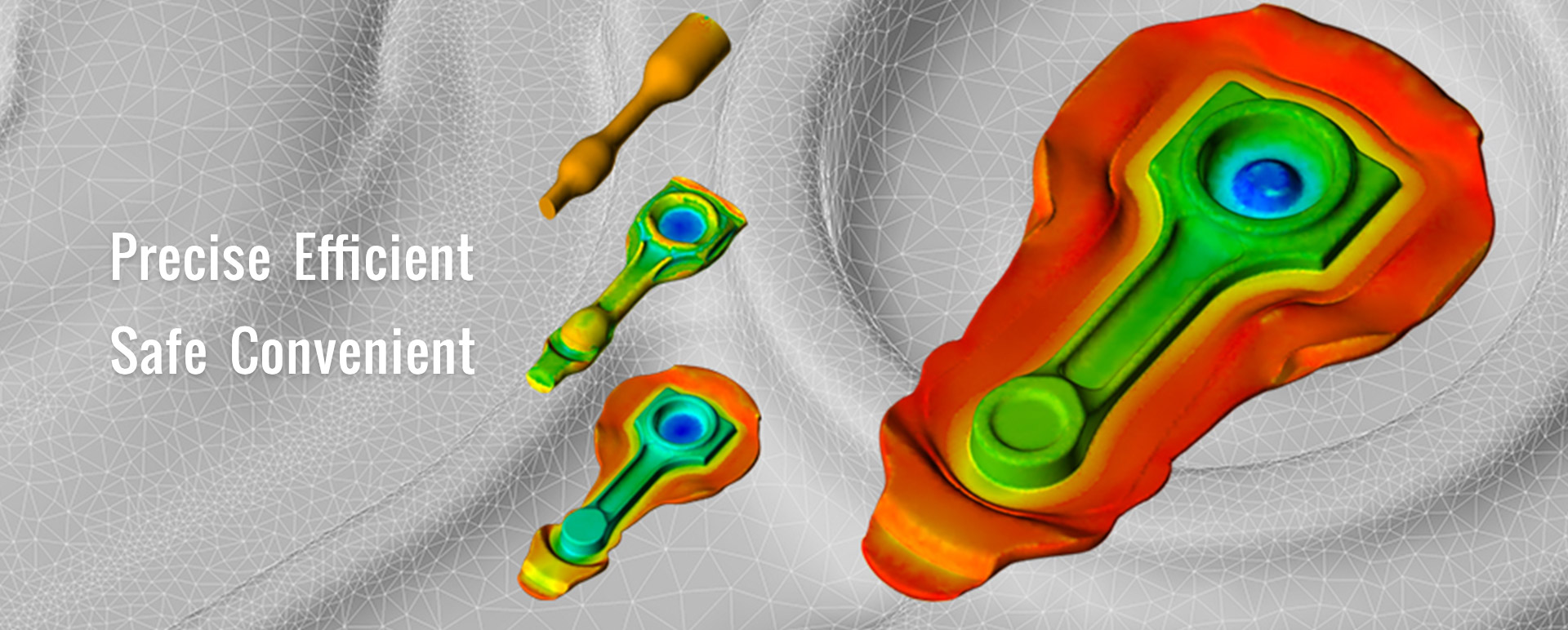

J58KA series CNC Electric Screw Press adopts advanced intelligent frequency conversion controlsystem, blow energy can be digitally controlled, forging precision is high, repeatability is good,structure is simple and reliable, easy to maintain, forging noise is low, and it takes into account thedual properties of hammer and press. It is a green and environmentally forging equipment withstrong process adaptability. It has unique advantages in the forging of non-ferrous metal, such asaluminum alloy and copper.