CNC Forging Hammer Production Line For Steel Ball

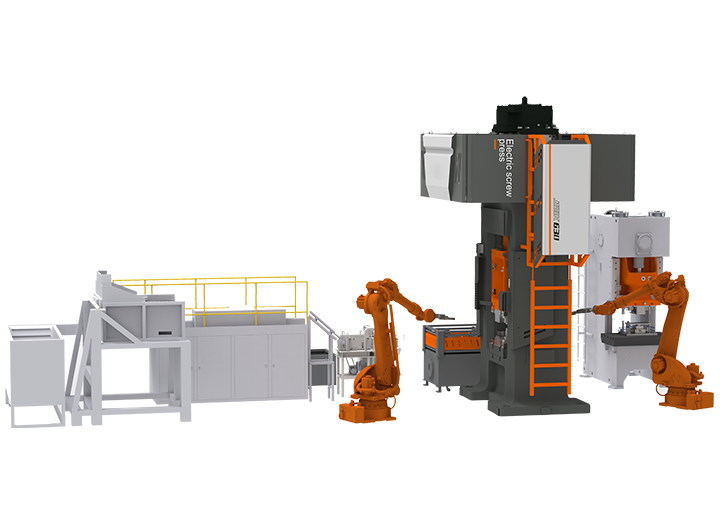

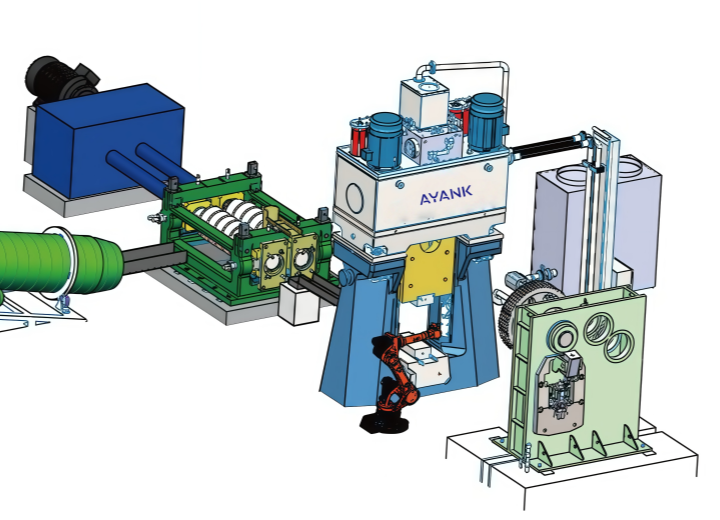

Medium frequency induction furnace--Billet shearing machine--Robot--CNC forginghammer--Rolling machine--Heat treatment.

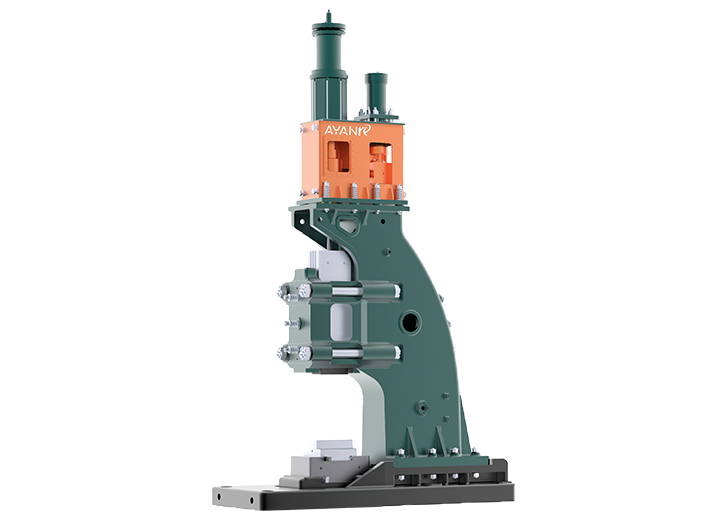

Considering equipment cost, production cost and labor cost, we use the forming method of"forging-rolling combination" to produce larger diameter steel ball. The process is as following:After the bar is heated by medium frequency furnace, is cut by billet shearing machine in short to the required length, the qualified material is sent to the CNC forging hammer by the robot, the preformed "upset ball" scrolls into the rolling machine through the trough under the action of gas cylinder, the rolling machine rolls the “upset ball” into good shape of steel ball, then after the heat treatment, get high hardness of wear-resistant ball.

Forging and rolling process theoretically can produce a variety of steel balls with various diameters.but due to investment and efficiency reasons, usually suitable for mass production of Ф100-Ф200mm steel ball, which has made better return on investment.