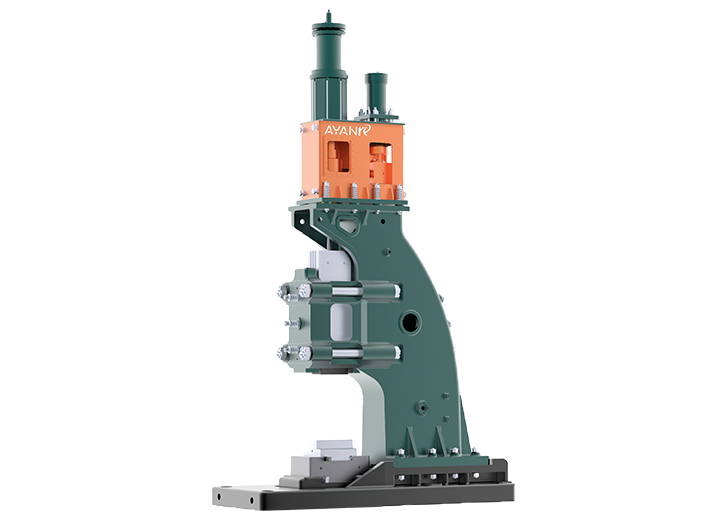

CNC Fully Hydraulic Die Forging Hammer (C92KA 16-450kJ)

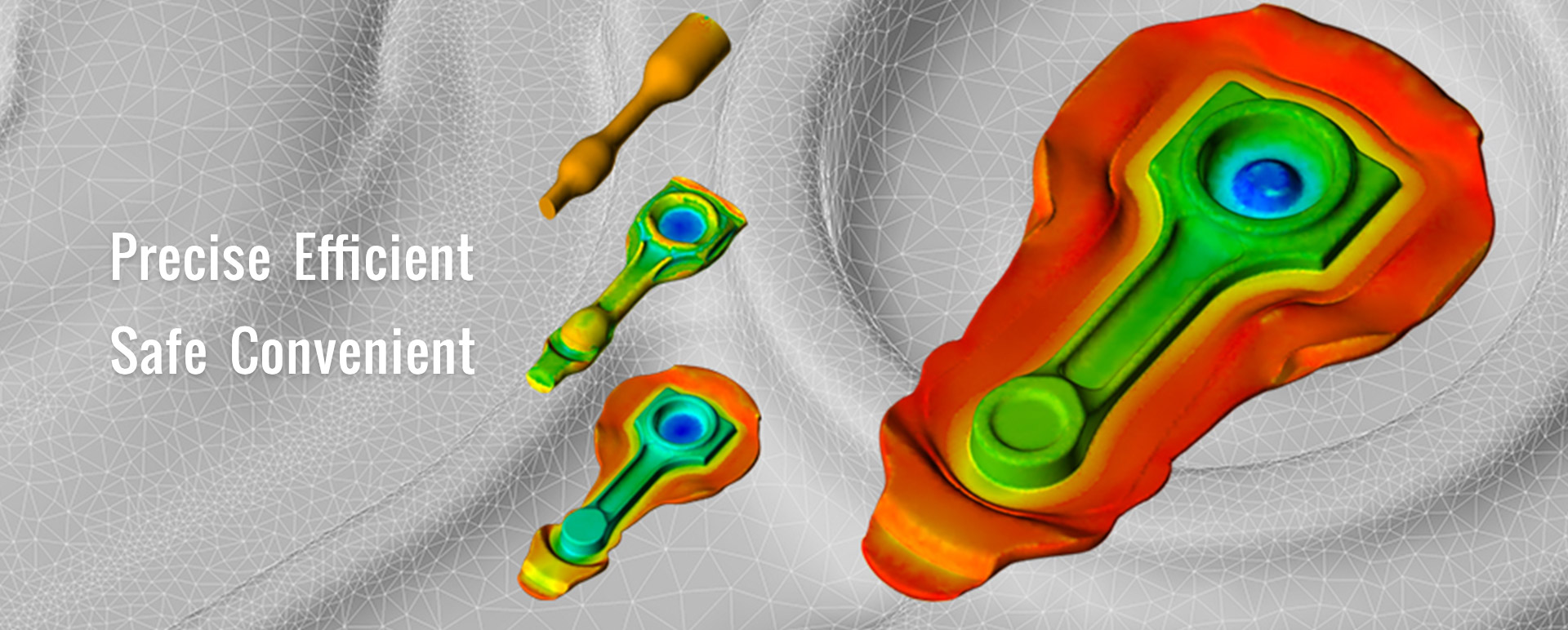

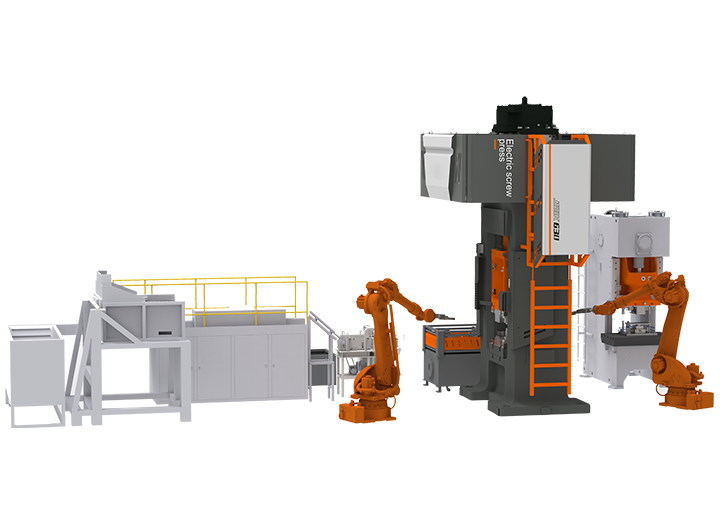

The C92K series of CNC fully hydraulic die forging hammers are suitable for mass production of multiple varieties in precision die forging industries such as automobiles, motorcycles, engineering machinery, hardware tools, and medical equipment. In addition, it is also widely used in high-density special-shaped parts such as the aerospace industry and is the core equipment of automated precision forging production lines.