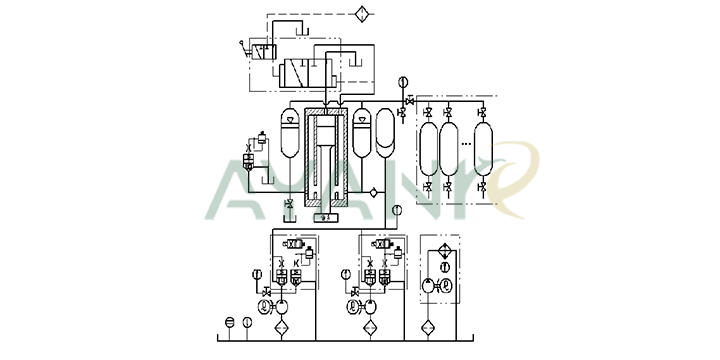

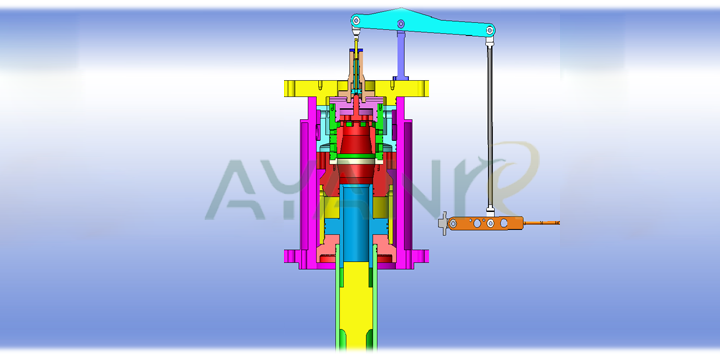

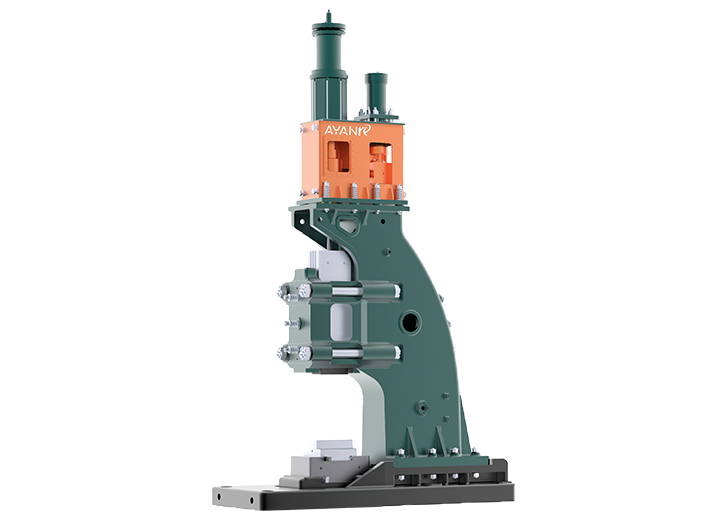

Fully Hydraulic Die Forging Hammer (C86YA 25-450kJ)

C86YA series Fully Hydraulic Die Forging Hammer adopts fully hydraulic drive system, lowerchamber of hammer piston rod is always connected with high-pressure oil, blow and returnstrokes are achieved by controlling oil pressure in the upper chamber ofthe piston. Advantagesare sufficient energy, high frequency, no mold stuck, low failure rate, and can achieve anyposition of hanging ram. Suitable for producing various types of die forgings.