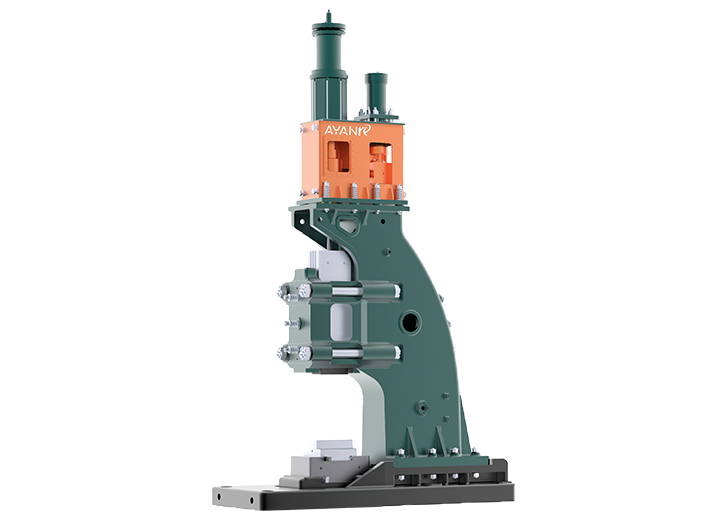

Fully Hydraulic Free Forging Hammer (C66YA 35-630kJ)

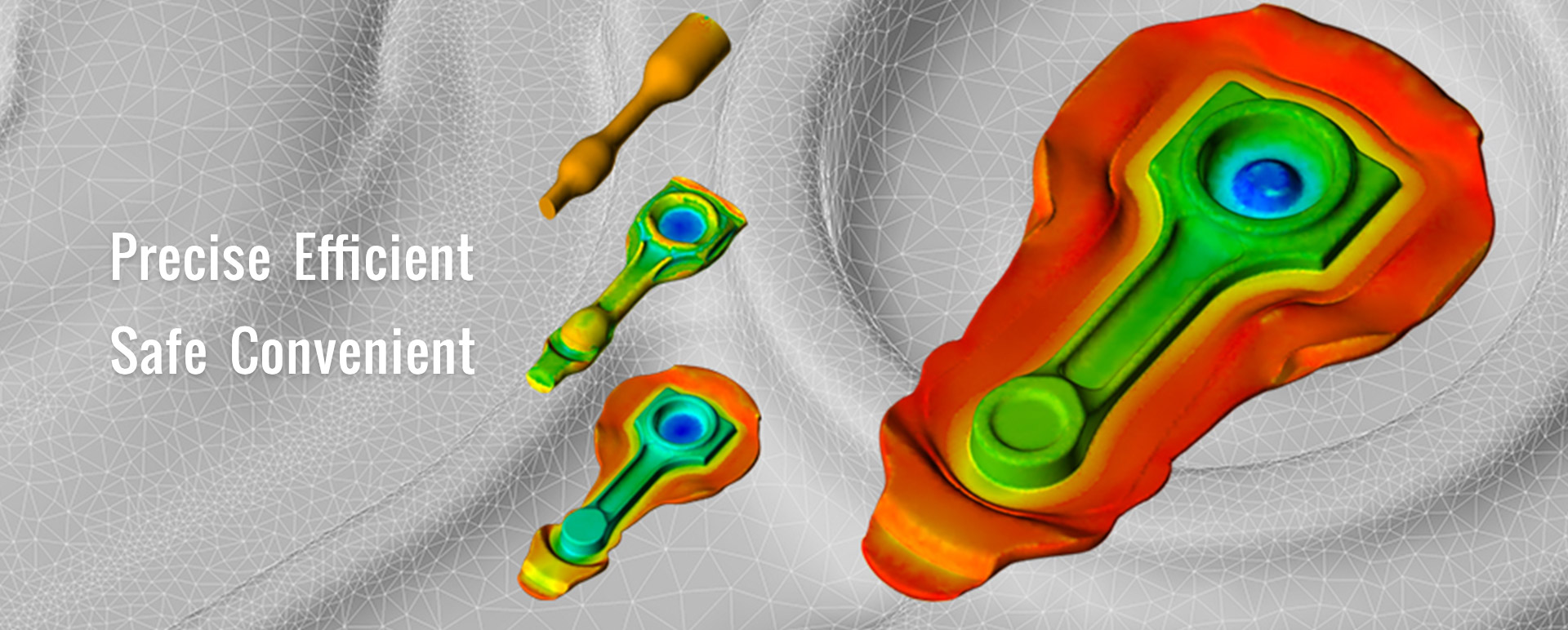

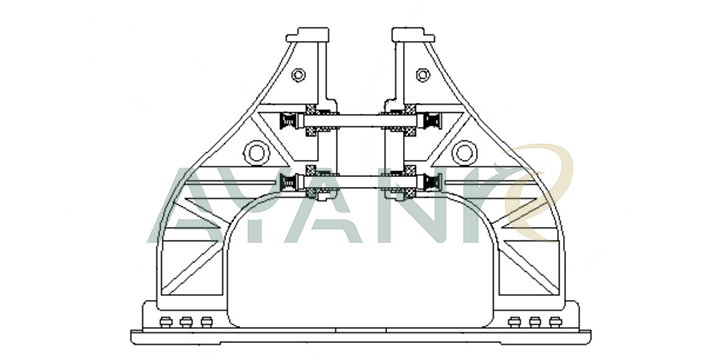

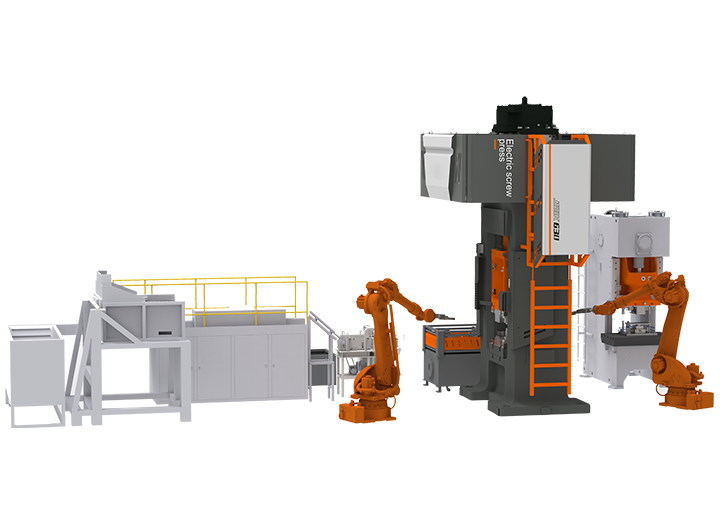

C66YA Series Fully Hydraulic Free Forging Hammer adopting an all-hydraulic drive system, this forging hammer delivers rapid striking and return speeds for enhanced production efficiency. Its flexible and easily controllable operation enables hammer suspension at any position, making it suitable for diverse free forging processes. Widely applied in manufacturing various types of free forgings, it is the preferred equipment for medium-to-large forgings and high-temperature alloy forgings.