Skew Rolling Machine Production Line for Steel Ball

Introduction

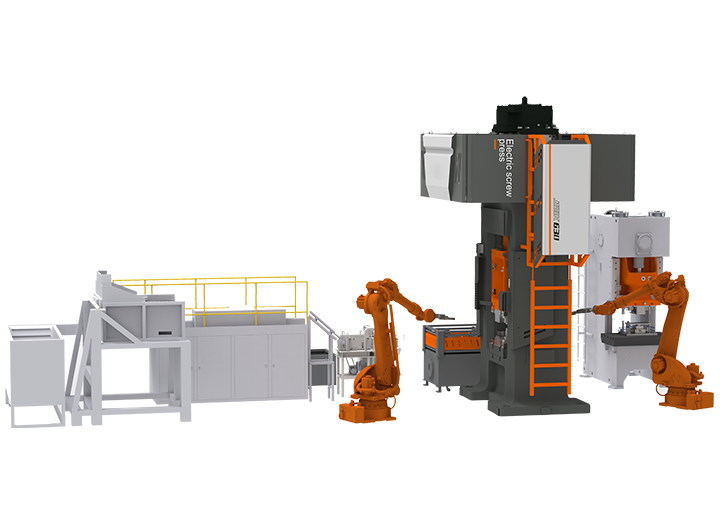

Ball rolling is the process of continuously deforming the heated bar on a skew rolling mill to obtain steel balls. The process is as following: the whole bar is heated by induction furnace - continuous rolling by the skew rolling mill - the subsequent heat treatment.Ball rolling process is highly automatic, and the production efficiency is much higher than that of ball forging line. It can produce steel balls with a diameter upto Φ125mm. Ball rolling line is also used for mass production and requires high power in the production workshop.Steel ball skew rolling mill is an automatic production equipment for steel ball, suitable for producing steel balls of various materials: medium carbon steel, manganese steel etc. The steel ball produced are widely used in mining, steel plant, chemical industry, building material, cement, metallurgy, thermal power plant and other industries. They are equipped with fully automatic heating equipment and transmission equipment to realize automatic production.

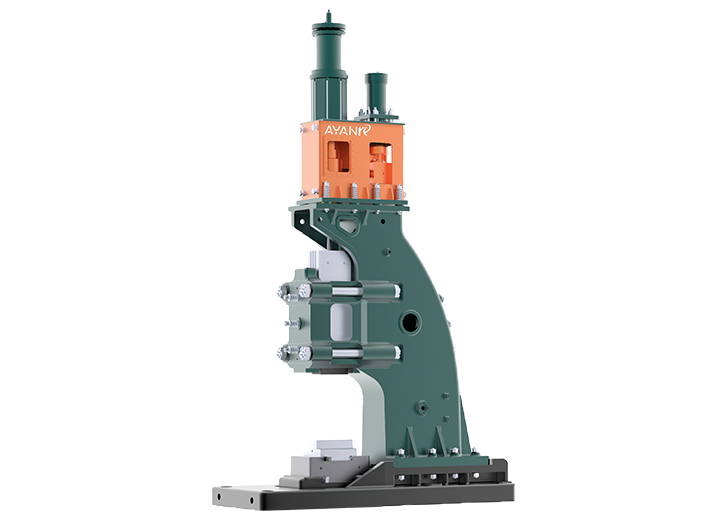

Features of skew rolling mill

Working load is small, because it is partially contin uously formed

High production efficiency, 3-10 times that of other processes

Ball dimensional accuracy is high

The metal streamline fiber of the steel ball are distributed along the shape of the part, and the steel ball has high load-bearing capacity

Good working environment, low vibration and noise, and can be achieved automatic production

Features of rolled steel balls

Surface quality of steel ball is good

Hardness of inside and outside of the steel ball is balanced (hardness difference <5HRC)

Low breakage rate and long service life

Steel balls have high density and strong impact toughness

High cost-effective, significant cost saving