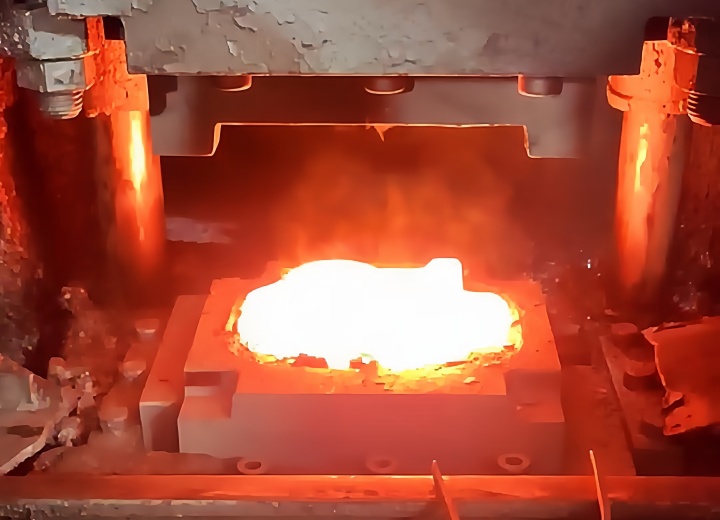

Hot Die Forging Press

-

Static Pressure Effect: Unlike the impact force of a forging hammer, the press provides slow, steady static pressure. This allows the deformation to penetrate deep into the core of the metal billet, resulting in a more refined grain structure and denser internal composition. Consequently, the comprehensive mechanical properties of the forging—such as strength, toughness, and fatigue resistance—are significantly enhanced. -

Complete Grain Flow Lines: The metal's grain flow lines can fully align along the die cavity without being cut off. This greatly increases the component's service life when enduring impact and alternating loads.

-

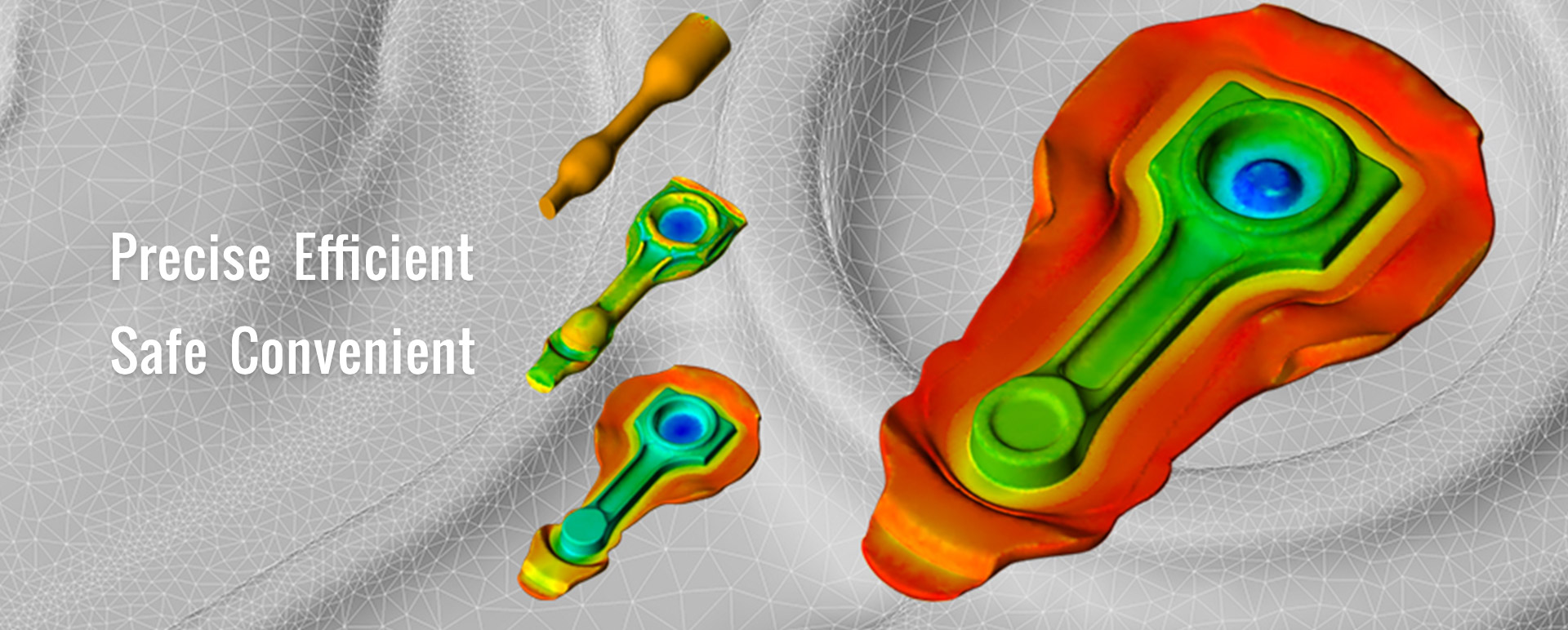

As the forming process takes place within a closed die cavity, the dimensions of the forging are guaranteed by the precision of the dies themselves. This ensures dimensional stability, tight tolerances, and enables near-net-shape manufacturing, which reduces the need for subsequent machining. -

The process yields forgings with excellent surface finish and minimal defects.